In the 3D Factory we print and construct your 3D models and advise you from the idea to the finished product.

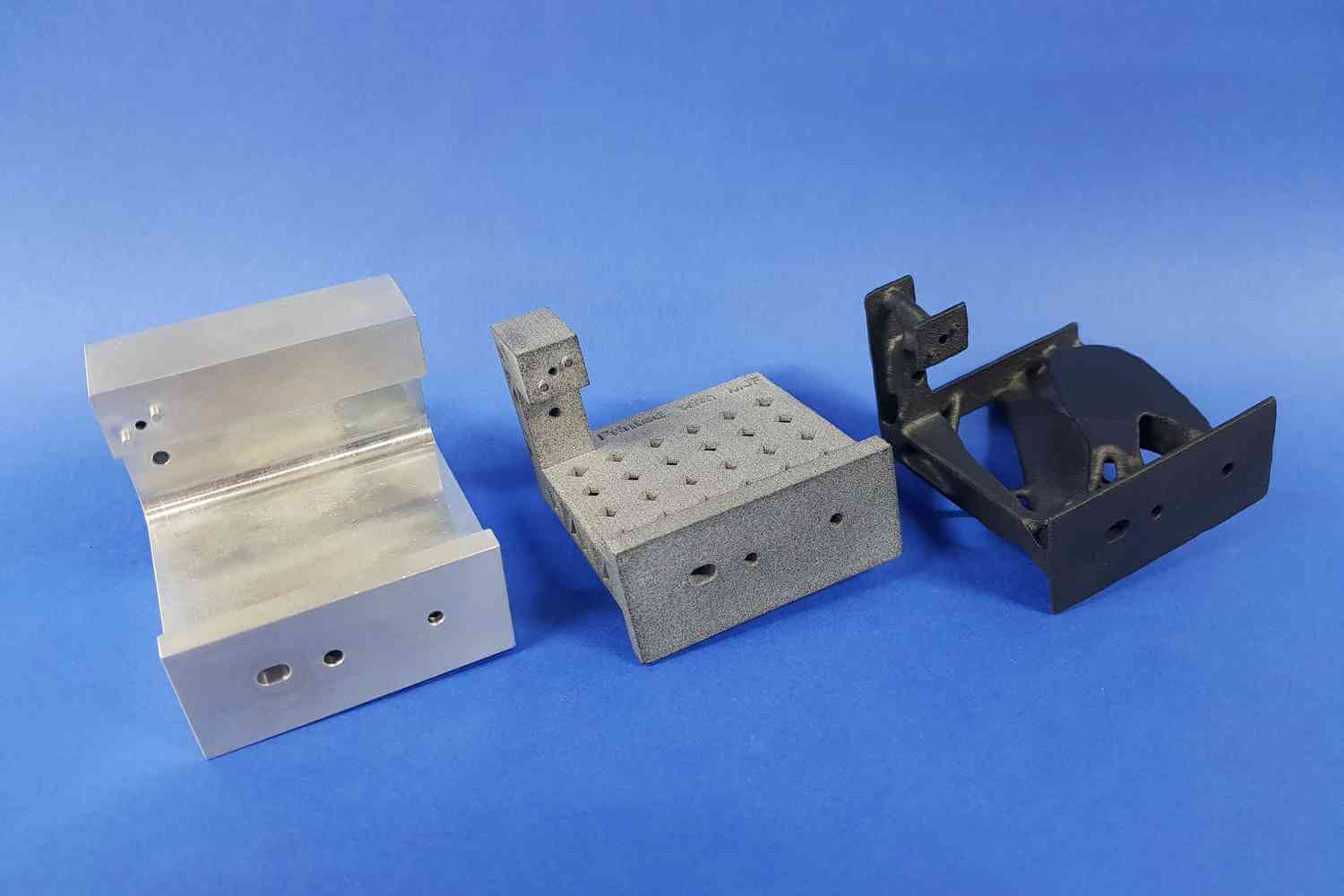

We have various technologies such as FDM(Fused Deposition Modeling), SLA(Stereolithography) and MJF(Multi Jet Fusion). The right choice of 3D printing technology is crucial for the required quality and price.

For example, it is not absolutely necessary for a simple prototype to have a visually attractive part if you only want to check function and collision. Therefore, the optimal choice is a fast, inexpensive technology with appropriate materials.

For a complex and stable end product, on the other hand, you need a well-fusing technology such as MJF powder printing, which can do without support structures.

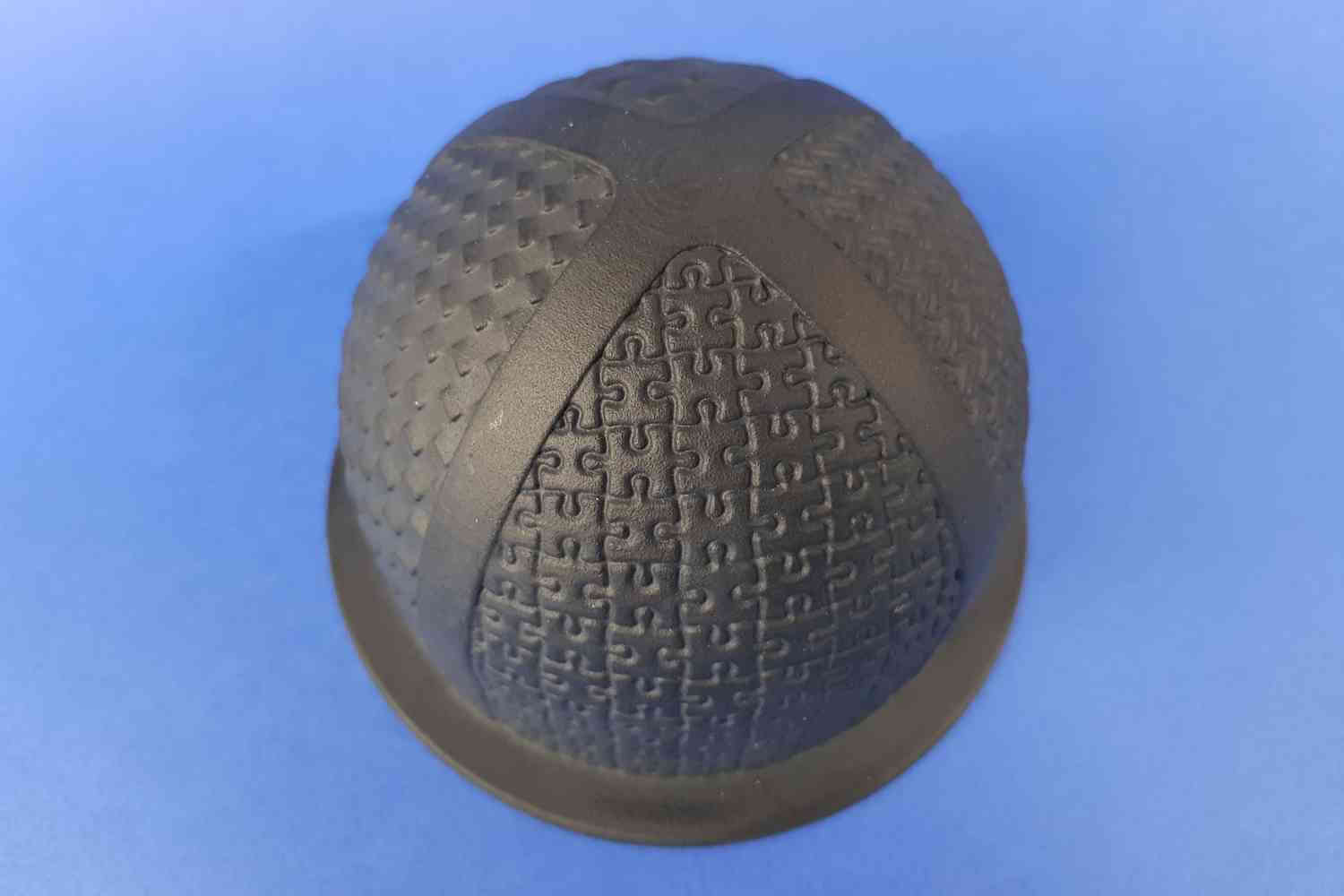

A detailed and decorative 3D model needs a 3D printer with a fine resolution. SLA printers with resin (liquid synthetic resin) are ideal.

The cost of a model can vary greatly. Many factors play a decisive role in 3D printing, e.g. Material, size, complexity, stability and quality. These factors influence the required printing time and thus a large part of the costs incurred.

In general, the larger, more precise and more stable a product is, the higher the printing time, the material consumption and the costs of the printing process.

As you can see, every 3D model has its own characteristics and the 3D printer should be chosen accordingly.

For an inquiry, write us an email or use the contact form. Please give as precise information as possible about your ideas regarding quality, stability and intended use.

Instagram

FDM prints

Raise3D Pro2 / 305x305x300mm / 2 colors

MJF prints

HP MJF4200 / 380x284x380 / PA12 / ± 0,3%

SLA prints

Formlabs Form 3 / 145x145x185mm / 25 – 300μm

CAD construction

Construction of 3D models according to your specifications.